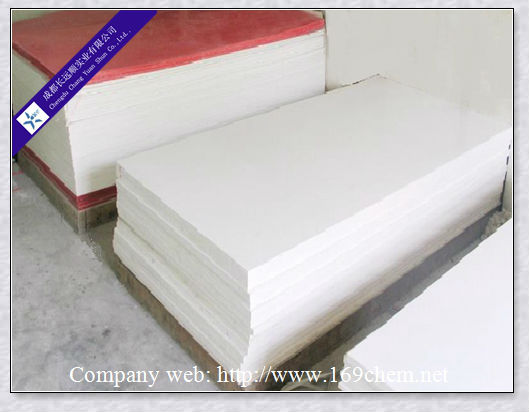

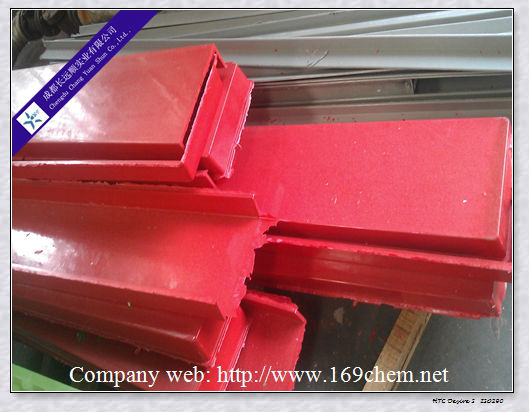

SMC Insulating sheets

GOP3 insulating sheet

SMC Insulating Sheet is made from chopped fiberglass strands impregnated with unsaturated polyester resin through high temperature and high pressure molding process. It is a kind of excellent FRP insulator. The SMC Insulating Sheet can be made into various colors.

APPLICATIONS.

- Mechanical / Electrical Application: electronic insulating board of high or low voltage switchgears, insulation structural parts, air conditioner bases, mechanical parts, machine & instrument casings, electronic / electric laminated sheet boards, etc.

-Transportation Application: Car door panels, hoods, cable boxes, odometers, instrumental panels, shades, etc.

- Building Materials: Door panels, water tanks, purification tanks, ceiling panels, wall panels, bathroom water proof panels, sinks, bathtubs, etc.

- Furniture Industry: Chairs, tables, work table face panels, student desks & chairs, screens, etc.

Product characteristics:

High mechanical strength.

Good flame retardancy

Flame retardancy and proof tracking

Excellent dielectricity, high voltage resistance

Low water absorption ratio, Good Dimensional Stability and low warp

Specifications

|

Regular sizes |

Color |

|

2500mm*1500mm*3~30mm |

Various colors: White, black, red, green, blue, yellow, orange, etc. |

|

2440mm*1220mm*3~30mm |

|

|

2000mm*1300mm*3~40mm |

|

|

2000*1000mm*2~40mm |

|

|

850*850*2~60mm |

|

|

Note: Other specifications can be made upon clients’ requests. |

|

Technical Parameters

|

|

Standard |

GB/T 23641-2009, Q/DFJ-01-2009, Q/DFJ-02-2009 |

||||

|

Serial No. |

Properties |

Unit |

Value |

|||

|

SMC-0 |

SMC-1 |

SMC-2 |

||||

|

1 |

Density |

g/cm³ |

1.7~1.9 |

1.7~1.9 |

1.7~1.95 |

|

|

2 |

Water Absorption |

Mg |

≤15 |

≤15 |

≤20 |

|

|

3 |

Shrinkage Rate |

% |

≤0.05 |

≤0.15 |

≤0.25 |

|

|

4 |

Heat Distortion Temperature (A) |

°C |

≥240 |

≥240 |

≥220 |

|

|

5 |

Thermal Endurance Index |

- |

≥155 |

≥155 |

≥140 |

|

|

6 |

Arc resistance |

S |

≥180 |

≥180 |

≥150 |

|

|

7 |

Impact strength (Charpy non-notch ) |

JS/m2 |

≥90 |

≥60 |

≥50 |

|

|

8 |

Bending strength |

Mpa |

≥170 |

≥160 |

≥140 |

|

|

9 |

Insulation resistance |

At room temp. |

Ω |

≥1.0*1013 |

≥1.0*1013 |

≥1.0*1012 |

|

|

After 24h in water |

≥1.0*1012 |

≥1.0*1012 |

≥1.0*1010 |

||

|

10 |

Dielectric Strength(in transformer oil at 90°C) |

MV/m |

≥12 |

≥12 |

≥10 |

|

|

11 |

Proof Tracking Index ( PTI ) |

V |

≥600 |

≥600 |

≥600 |

|

|

12 |

Flammability |

Grade |

F V0 |

F V0 |

F V1 |

|

|

13 |

Relative Permittivity 1MHz |

- |

≤4.5 |

≤4.5 |

- |

|

|

14 |

Dissipation Factor (1MHz) |

- |

≤0.015 |

≤0.015 |

- |

|

|

15 |

Withstand Voltage (1 min in air) |

KV |

See the following Table 1# |

|||

Note: Special technical requirements are negotiable.

Table 1#

|

Nominal Thickness |

3mm |

4mm |

5~6mm |

>6mm |

|

Withstand Voltage (1 min in air) |

≥28KV |

≥35KV |

≥42KV |

≥50KV |