Gun Roving

Gun roving also called chopper gun roving, spray up roving which is mainly compatible with reinforced unsaturated Polyester, Vinyl ester resin and Polyurethane resin and so on.

It is mostly used to produce FRP boat hulls, safe board, sanitary apparatus and swimming pools etc.

|

Type of glass |

E |

|

Filament diameter (um) |

12 |

|

Linear density (Tex) |

2400, 4800 |

Product Feature:

1. Good choppability and good gathering.

2. Good diversion and low static.

3. Excellent lay down property.

4. Excellent mold flowability & fast wet out.

Technical Parameters:

|

Linear density |

Filament diameter |

Moisture content |

LOI |

|

±5% |

13±1um |

≤0.10 |

1.10±0.15 |

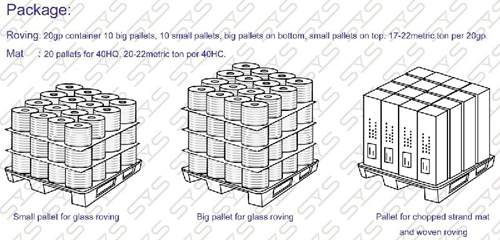

Packing:

The product can be packed on pallet in both small & big size pallet.

|

Bobbin height (mm) |

260 |

|

|

Bobbin inside diameter (mm) |

80 |

|

|

Bobbin outside diameter (mm) |

270 |

|

|

Bobbin weight (kg ) |

18-20 |

|

|

Number of layers |

3 |

4 |

|

Number of rolls per layer |

16 |

|

|

Number of rolls per pallet |

48 |

64 |

|

Net weight per pallet (kg) |

864-960 |

1152-1280 |

|

Pallet length (mm) |

1140 |

1140 |

|

Pallet width (mm) |

1140 |

1140 |

|

Pallet height (mm) |

955 |

1220 |

Storage:

Fiberglass roving should be stored in its original packing in a dry and cool place. Best conditions are at temperatures from 15 to 35℃ and humidity between 35 to 65%. To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high, when the pallets are stacked in 2 or 3 layer, care should be taken to correctly and smoothly move the top pallet.