AR spray roving ZrO2 14.5%

AR GLASSFIBRE SPRAY ROVING is an AR glass chopping roving mainly designed for use in the manufacture of GRC composites by the manual spray method. SPRAY ROVING is suited to Portland cement for reinforcement. It is used in the manufacture of GRC architectural panels and other building elements, civil engineering and infrastructure components.

Example: ARC13-2700H

AR: Alkali Resistant

C: Continuous fiber

13: Filament diameter

2700: Nominal linear weight of roving (tex)

H: ZrO2 content 16.7%

Properties

1. Easy chopped

2. Good integrity and disposability

3. Excellent alkali resistant and durability

Technical Characteristics

|

Product |

Bobbin /pallet |

Pallet |

|||

|

Length (mm) |

Width (mm) |

Height (mm) |

Net weight (kg) |

||

|

ARC15-2400L |

48 |

1130 |

1130 |

1000 |

860 |

|

48 |

1130 |

1130 |

1000 |

1000 |

|

|

64 |

1130 |

1130 |

1300 |

1150 |

|

Products Available

AR GLASSFIBRE SPRAY ROVINGS is designed to be unwound internally. They are protected by a shrink-wrap polythene film which should not be removed when used. Each roving is identified by an individual label and packed in a carton. AR GLASSFIBRE SPRAY ROVINGS 14.5% is white colored but an orange color is used on labels and shrink-wrap to aid identification.

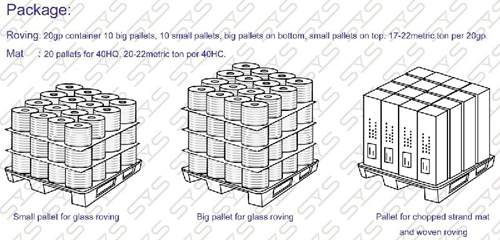

Pallet Packing

1. Each pallet has 3 or 4 levels, 16 rolls /level.

2. The complete pallet is enclosed in polythene and identified with two labels.

Shipment

For sea transport, a maximum of 20 pallets (on two levels) may be loaded in a 20 foot container, giving a total net weight of approximately 17-20 tons.

Storage

AR GLASSFIBRE SPRAY ROVING should be stored dry in their original packaging, the best conditions being at a temperature of between 15℃- 35℃ and at a relative humidity of between 35%- 65%. If the product is stored at low temperature (below 15℃) it is advisable to condition in the workshop for 24 hours before use to prevent condensation.

Quality

AR GLASSFIBRE SPRAY ROVING is produced according to ISO9001:2008 quality control system.